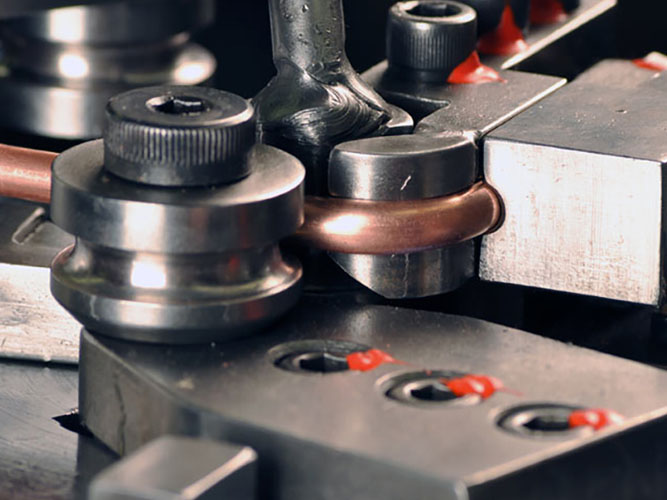

CNC Bending

Our CNC bending services leverage advanced technology and skilled craftsmanship to deliver high-quality, precisely bent components for a wide range of industrial applications, ensuring accuracy, efficiency, and excellent performance.

Material Capabilities:

- Types of Materials: Supports a range of metals including stainless steel, mild steel, aluminum, and alloys.

- Thickness Range: Capable of bending materials with thicknesses from 0.5 mm to 12 mm, depending on the material type and machine specifications.

- Sheet Dimensions: Handles sheet lengths up to 3 meters and widths up to 1.5 meters, accommodating various sizes and specifications.

Bending Capabilities:

- Machine Types: Utilizes advanced CNC press brakes and hydraulic bending machines for precise and consistent results.

- Bending Angles: Capable of achieving precise angles from 0 to 180 degrees with high repeatability.

- Complex Geometries: Supports complex bending operations including multi-axis bends, box bends, and custom profiles.

Process Features:

- CNC Control: Sophisticated CNC controls enable automated and programmable bending sequences, ensuring accuracy and reducing manual errors.

- Tooling: Equipped with a variety of tooling options such as punches, dies, and tooling setups tailored to specific bending requirements and materials.

- Back Gauge: Automated back gauge systems for accurate positioning and alignment of materials during the bending process.

Finishing and Quality Control:

- Precision: High precision in achieving tight tolerances and consistent bending angles across multiple parts.

- Inspection: Comprehensive quality control processes, including dimensional checks and visual inspections, to ensure parts meet specified tolerances and quality standards.

- Certifications: Adheres to industry standards and certifications to guarantee the reliability and quality of finished products.

Production Capabilities:

- Custom Bending: Provides tailored solutions for custom bending requirements, including prototypes and high-volume production runs.

- Rapid Turnaround: Efficient processing for quick turnaround times on both small and large-scale projects.

Technical Support:

- Engineering Expertise: In-house engineers and technicians offer technical support, design assistance, and optimization of bending processes.

- Client Collaboration: Engages closely with clients to understand their specifications, provide design recommendations, and ensure that final products meet all requirements.